MIG / MAG welding process POWER.PULS

Overview of the highlights

- Aluminum (Al): 1.0 to 15.0 mm

- CrNi: 1.0 to 8.0 mm

- Anwedung: Spezialist für Aluminium (Al) & ideal für dünne CrNi-Bleche

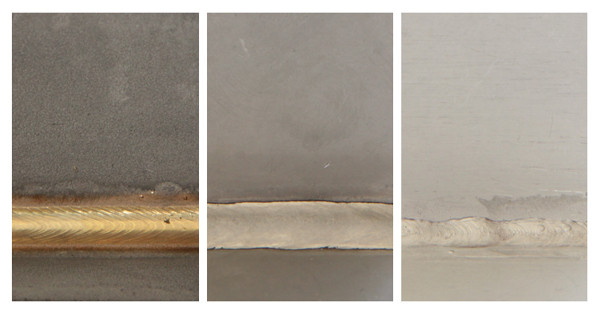

- MIG-Löten: Hervorragende Eigenschaften

II-geregelter Schweißprozess

Der REHM POWER.PULS II wird in erster Linie für Materialien eingesetzt, bei denen die gleichmäßige Tropfengröße, sowie eine guten Benetzung wichtig ist. Damit ist es ideal einsetzbar für Aluminium und Edelstahl-Dünnbleche bis 3 mm Stärke.

POWER.PULS

The all-round welding process

Der Nutzen

Die Lichtbogenlänge kann über die Spannung oder den Drahtvorschub eingestellt werden. Zusätzlich kann die UI-Regelung schneller auf Veränderungen reagieren als die normalerweise übliche II-Regelung. Das ermöglicht ein sehr schnelles Finden der idealen Einstellung durch den Anwender.