TIG welding process HYPER.PULS

Overview of the highlights

- Materialstärke: Ab 0,1 mm

- Schweißnaht: Ergebnisse ähnlich dem Laser-Schweißen

- Frequenz: Bis zu 17,5 kHz

- Geräusche: Nahezu unhörbarer Lichtbogen

Der REHM HYPER.PULS

Das Pulsen ist eine Schweißtechnik, die abhängig von den Schweißanforderungen sehr konkrete Vorteile mit sich bringt. Jedoch ist bei den meisten WIG-Impulsschweißgeräten der übliche Frequenzbereich problematisch für den Schweißer. Der HYPER.PULS-Schweißprozess mit den entsprechenden Impulsschweißgeräten von REHM löst diese Problematik souverän und eröffnet noch dazu weitere Vorzüge, welche die Wirtschaftlichkeit enorm steigern.

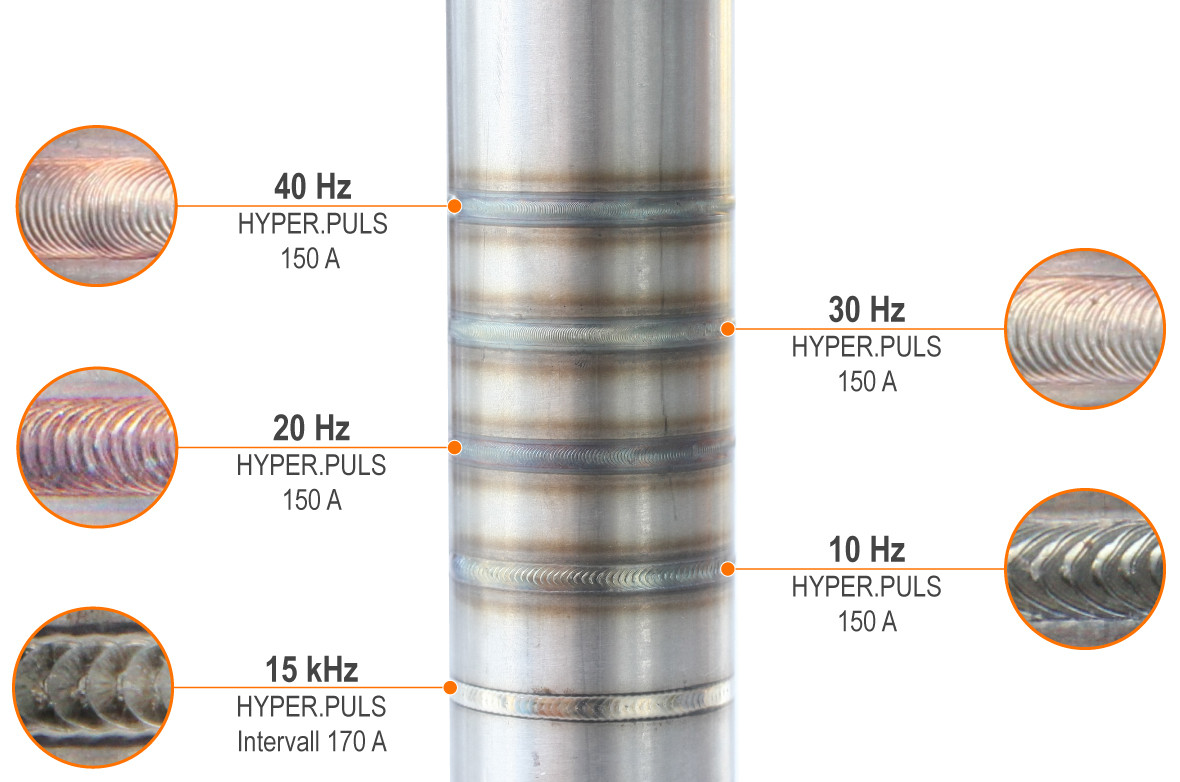

Das WIG-Impulsschweißen

Beim Impulsschweißen liegt einer der wesentlichen Vorteile darin, dass das Schmelzbad sehr schmal ausgeführt wird. Darüber hinaus erstarrt das Schmelzbad abhängig von der Frequenz außen schneller, sodass auch sehr dünne Metalle geschweißt werden können. Bei Metallen und Legierungen wie beispielsweise CrNi, die zu einem sich schnell einstellenden Schmelzbad führen, können Sie mit dem Pulsen die Parameter einfach anpassen für eine saubere Schweißnaht. Mit höheren Puls-Frequenzen im Kilohertz-Bereich lässt sich zudem die Schweißgeschwindigkeit signifikant erhöhen. Gegenüber dem herkömmlichen WIG-Schweißverfahren können Sie die Schweißgeschwindigkeit mindestens verdoppeln.

Ein besonders hoher Frequenzbereich für besonders leises Schweißen

Jedoch liegt ein wesentlicher Nachteil der meisten Puls-Schweißgeräte im Frequenz-Arbeitsbereich beim Hochfrequenz-Impulsschweißen. In der Regel liegt dieser zwischen 2.000 und 6.000 Hz, also zwischen 2 und 6 kHz. Das ist problematisch, denn das menschliche Gehör arbeitet im Frequenzbereich zwischen 2 und 8 kHz. Das Pulsen in diesem Bereich ist ausgesprochen unangenehm und auf Dauer eine massive Belastung. Mit dem REHM HYPER.PULS können Sie das Schweißgerät auch darüber bis zu 17,5 kHz einstellen. Bei Frequenzen von bis zu 17.500 Hz ist das Schweißen für den Schweißer so gut wie nicht mehr hörbar.

Geschweißt mit WIG-Schweißgerät TIGER® digital unter Zurhilfenahme eines Drehtisches

Sehr nah am Laserschweißen - nur ohne dessen hohe Anschaffungskosten

Ein weiterer Vorteil liegt im Auftreten des Lorentz-Effekts. Dabei zieht es das sich konzentrisch um den Lichtbogen bildende Magnetfeld nach innen. Da diese Kraft mit der Stromdichte zunimmt, wird auch der Lichtbogen geschnürt. Das wiederum führt zu einem deutlich stabileren Lichtbogen, der gegenüber anderen Schweißverfahren nicht mehr so stark abgelenkt wird.

Außerdem kann der Lichtbogen einfacher über das zu schweißende Werkstück geschoben werden, da er nicht wie sonst zu beobachten so stark im Schmelzbad klebt. Das Schweißen ist dann dem Plasmaschweißen sehr ähnlich, beim eingeschnürten Lichtbogen lassen sich zudem ähnlich hochwertige Schweißnähte wie beim Laserschweißen erzielen. Nur, dass die WIG-Impulsschweißgeräte deutlich preiswerter sind als ein Laserschweißgerät.

Zusammenfassung: der HYPER.PULS von REHM bietet herausragende Vorteile

Das WIG-Pulsen ermöglicht das Schweißen auch geringer Blechstärken ab 0,1 mm. Dennoch kann die Durchbrandgefahr völlig minimiert werden bei einer gleichzeitig schmaleren Schweißnaht, die aber so gewählt werden kann, dass sie sich exakt auf die Blechstärke abstimmen lässt. Der eingeschnürte Lichtbogen erhöht die Schweißgeschwindigkeit erheblich. Abhängig von der Stromstärke kann das Schmelzbad so definiert werden, dass es im Außenbereich bereits erstarrt,

während Sie fügen. Das ermöglicht auch einfaches und effizientes Arbeiten in Zwangslagen. Den Frequenzbereich können Sie gegenüber den meisten Impulsschweißgeräten bis auf 17,5 kHz erhöhen. Damit ist das HYPER.PULS-Pulsen von REHM nahezu nicht mehr hörbar. Die Schweißqualität reicht nahe an die beim Laserschweißen heran, jedoch ohne die damit verbundenen hohen Investitionskosten.

Which welding machines have this process?

TIGER® digital 182 to 230 ULTRA

- Setting range: up to 230 A

- Duty cycle: up to 40 %

- Mains: 230 V - 50/60 Hz

- Protection type: IP 23 S

- Weight: from 7.1 kg

- HYPER.PULS: 17,5 kHz

INVERTIG.PRO® digital 240 to 450

- Setting range: up to 450 A

- Duty cycle: up to 100 %

- Mains: 400 V - 50 Hz

- Protection type: IP 23

- Weight: from 25 kg

- HYPER.PULS: 15 kHz