TIG welding process HYPER.SPOT

Der REHM HYPER.SPOT

Aus unterschiedlichen Gründen heraus müssen Bauteile auch gepunktet oder geheftet werden. Entweder handelt es sich um temporäres Fügen oder das Schmelzbad darf nicht zu tief in das Werkstück eindringen. Die Anforderungen beim Heften oder Punkten sind hoch. Mit den HYPER.PULS-WIG-Schweißgeräten von REHM können Sie diese hohen Anforderungen über das HYPER.SPOT Konzept souverän erfüllen.

Das Heften mit HYPER.SPOT-Technologie von REHM

Grundsätzlich ist das Pulsen mit entsprechenden WIG-Impulsschweißgeräten hervorragend zum Heften oder Punkten geeignet. Jedoch sind beim Heften häufig unterschiedliche Schwierigkeiten zu meistern. Gerade beim Punkten stellt das Zünden des Lichtbogens eine Herausforderung dar. Der Wärmeeintrag als auch die Entstehung des Lichtbogens lassen sich bei vielen WIG-Schweißgeräten nicht so kontrollieren wie erforderlich.

Geschweißt mit WIG-Schweißgerät TIGER® digital

Mithilfe des ICS-Zündmanagements erfolgt eine zuverlässige Zündung - völlig unabhängig von der verwendeten Elektrode und dem eingesetzten Schutzgas. Gerade bei geringen Blechstärken zwischen 0,1 und 0,2 mm ist die Lichtbogen-Energie beim REHM HYPER.SPOT-Schweißen so gering, dass das zu fügende Werkstück keine Beschädigungen aufweist.

Basistechnologie: das WIG Pulsen HYPER.PULS von REHM

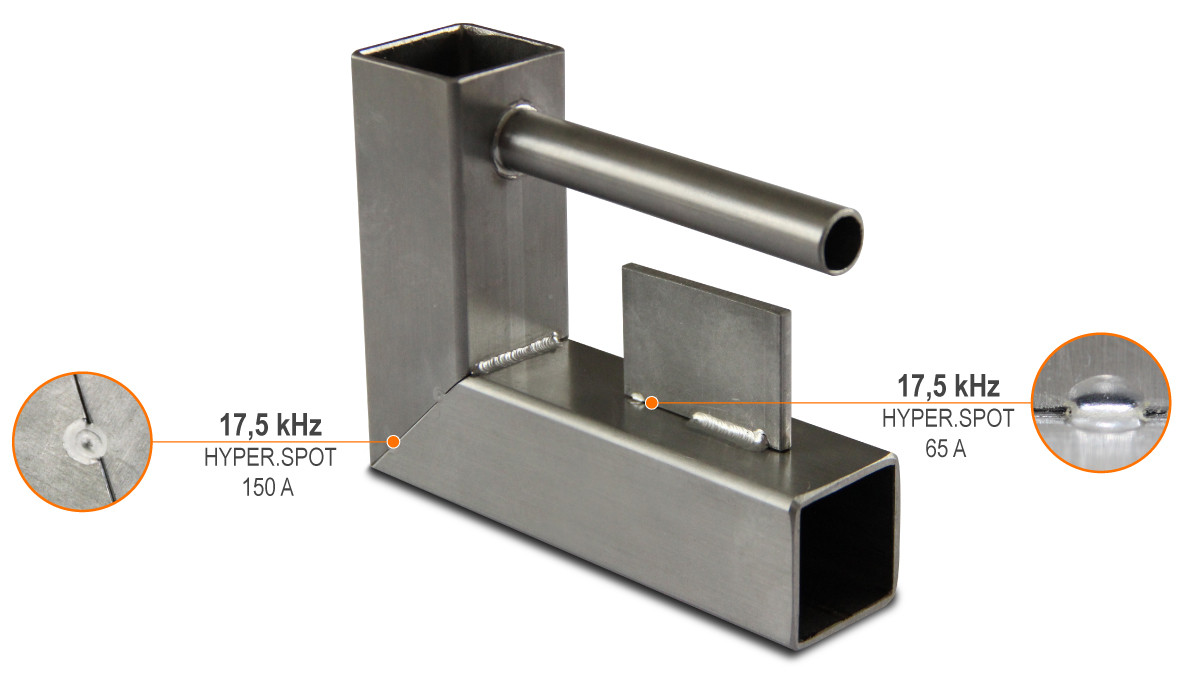

Selbstverständlich profitieren Sie beim Punkten ebenfalls von den Vorzügen der HYPER.PULS-Schweißtechnologie von REHM. Konkret bedeutet das einen stabilen und gleichmäßigen Lichtbogen bei deutlich schnellerem Schweißen. Außerdem "klebt" der Lichtbogen nicht im Schmelzbad fest. Auch wird das Schmelzbad schnell und präzise erreicht und erstarrt von außen ebenso zügig. Das schnelle Punkten führt zudem dazu, dass es kaum einen nennenswerten Wärmeeintrag in das Werkstück gibt. Unerwünschte Verformungen und Verfärbungen können so auch bei geringen Materialstärken des Werkstücks ausgeschlossen werden. Eine der wichtigsten Optionen beim REHM HYPER.PULS ist der hohe Frequenzbereich bis 17.500 Hertz.

Deutliche Vorteile gegenüber anderen WIG-Impulsschweißgeräten

Die meisten WIG-Impulsschweißgeräte arbeiten in einem Frequenzbereich von maximal 6.000 Hz. Dabei ist die Geräuschentwicklung extrem. Das menschliche Hören liegt jedoch hauptsächlich in einem Bereich bis 8.000 Hz. Dadurch ist das HYPER.PULS Impulsschweißen von REHM in den entsprechenden Frequenzen für das menschliche Ohr nahezu nicht hörbar. Das stellt einen signifikanten Vorteil dar. Darüber hinaus wird der Lichtbogen durch den Lorentz-Effekt in den hohen Frequenzen deutlich geschnürt, sodass das Pulsen mit den Impulsschweißgeräten von REHM nahe an das Laserschweißen heranreicht - nur, dass die hohen Investitionskosten wie für ein Laserschweißgerät nicht ansatzweise entstehen. Selbstverständlich können Sie mit Gleichstrom und Wechselstrom und auch Leichtmetalllegierungen wie Aluminium punkten.

Which welding machines have this process?

TIGER® digital 182 to 230 HIGH & ULTRA

- Setting range: up to 230 A

- Duty cycle: up to 40 %

- Mains: 230 V - 50/60 Hz

- Protection type: IP 23 S

- Weight: from 7.1 kg

- HYPER.SPOT: 17,5 kHz

INVERTIG.PRO® digital 240 to 450

- Setting range: up to 450 A

- Duty cycle: up to 100 %

- Mains: 400 V - 50 Hz

- Protection type: IP 23

- Weight: from 25 kg

- HYPER.SPOT: 15 kHz